- This topic is empty.

-

Topic

-

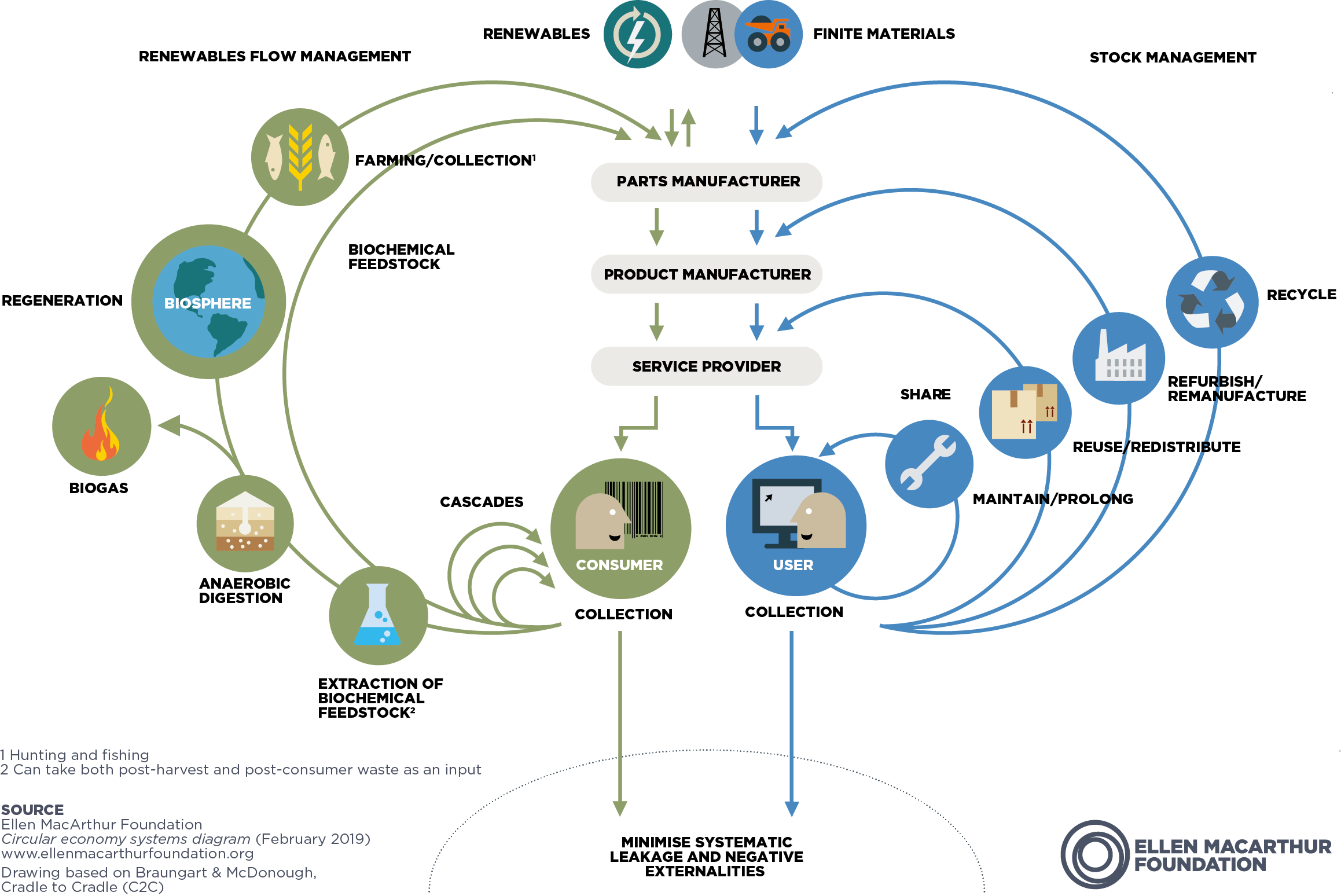

Circular design, also known as circular economy design or cradle-to-cradle design, is an approach to product and system design that aims to minimize waste, promote sustainability, and maximize the efficient use of resources. It is a response to the traditional linear economy model, which follows a “take-make-dispose” pattern, leading to resource depletion and environmental degradation.

It is based on the following principles:

- Design for longevity: Products are designed to have a longer lifespan, which reduces the frequency of replacements and the consumption of new resources. This involves selecting durable materials and components and considering repairability and upgradability.

- Design for resource efficiency: Circular design prioritizes the efficient use of materials and resources throughout a product’s lifecycle. This includes using recycled or renewable materials, minimizing waste during production, and designing for easy disassembly and recycling at the end of a product’s life.

- Design for reuse: Products are designed with the intention of being reused multiple times. This can involve modular design, where components can be easily replaced or upgraded, or designing products for second-hand markets.

- Design for recycling: Considers the entire lifecycle of a product, including its eventual disposal. Products are designed to be easily disassembled, and materials are selected with recycling in mind to reduce the environmental impact of the end-of-life phase.

- Design for reduced environmental impact: Takes into account the environmental impact of a product throughout its lifecycle, including energy use, emissions, and water consumption. Design choices aim to minimize these impacts.

- Design for biodegradability: In cases where recycling may not be feasible, circular design considers the use of biodegradable materials that can break down naturally without causing harm to the environment.

Not limited to physical products; it can also be applied to services, business models, and systems. The ultimate goal of circular design is to create a closed-loop system where products and materials are continuously cycled, reducing waste and minimizing the depletion of natural resources. This approach is seen as a key strategy for achieving sustainability and reducing the environmental impact of human activities.

Steps:

- Understand the Current System:

- Analyze your current product or system and its lifecycle to identify areas where waste is generated and resources are inefficiently used.

- Assess the environmental impact of your current processes and products.

- Set Clear Goals:

- Define specific and measurable sustainability goals that align with the principles of circular design. Consider factors like resource efficiency, waste reduction, and reduced environmental impact.

- Involve Stakeholders:

- Engage all relevant stakeholders, including designers, engineers, suppliers, customers, and policymakers, in the circular design process.

- Seek input and collaborate with partners to ensure a holistic approach.

- Rethink Design:

- Redesign your products, services, or systems with circular principles in mind.

- Consider factors like durability, modularity, ease of disassembly, use of recycled materials, and potential for reuse or recycling.

- Material Selection:

- Choose materials with a lower environmental impact and a potential for recycling or biodegradability.

- Prioritize materials that can be sourced sustainably and are available in closed-loop supply chains.

- Optimize Manufacturing:

- Implement sustainable manufacturing processes that reduce energy consumption, emissions, and waste.

- Explore methods like lean manufacturing and green chemistry to minimize environmental impacts.

- Establish a Take-Back System:

- Develop a system for collecting and refurbishing or recycling products at the end of their lifecycle.

- Consider incentives for customers to return products.

- Promote Reuse and Repair:

- Encourage and enable customers to repair and upgrade products rather than replacing them.

- Create programs or partnerships for extending the life of products through repairs.

- Communicate and Educate:

- Communicate the circular design philosophy to both internal and external stakeholders.

- Educate employees, customers, and partners about the benefits of circular products and services.

- Measure and Monitor:

- Establish key performance indicators (KPIs) to measure the progress and success of your circular design initiatives.

- Continuously monitor and assess the environmental and economic impact of your efforts.

- Iterate and Improve:

- Regularly review your circular design practices and gather feedback.

- Make necessary adjustments and improvements to align with your sustainability goals.

- Scale and Expand:

- As your circular design initiatives prove successful, consider scaling them up to encompass a broader range of products, services, or business operations.

- Explore opportunities to collaborate with other organizations to drive circular economy practices within your industry.

- Comply with Regulations:

- Stay informed about environmental regulations and compliance requirements in your industry and region.

- Ensure that your circular design efforts align with legal standards.

- Celebrate Successes:

- Acknowledge and celebrate achievements and milestones in your circular design journey to motivate and inspire further progress.

Circular design is an ongoing process that requires commitment, innovation, and collaboration.

Advantages

- Resource Efficiency: Promotes the efficient use of resources, reducing the need for virgin materials. This can lead to cost savings for businesses and reduced environmental impacts, including decreased resource depletion.

- Waste Reduction: By designing products for longevity, repairability, and recycling, circular design minimizes waste generation. This can lower disposal costs and reduce the environmental burden of waste management.

- Environmental Conservation: Helps conserve natural resources, reduce greenhouse gas emissions, and minimize pollution by extending the lifespan of products and promoting recycling.

- Economic Opportunities: The circular economy can create new business opportunities, such as recycling, remanufacturing, and repair services. It also encourages innovation in sustainable product design and materials.

- Enhanced Customer Loyalty: Customers increasingly value sustainability and eco-friendly products. Circular design can enhance brand reputation and customer loyalty by demonstrating a commitment to environmental responsibility.

- Resilience to Supply Chain Disruptions: Often involves shorter supply chains and local sourcing of materials, reducing vulnerability to global supply chain disruptions.

- Cost Savings: Over time, circular design can lead to cost savings in manufacturing, as it encourages the use of efficient processes, reduces material waste, and prolongs the life of products.

- Job Creation: The circular economy can create jobs in industries related to recycling, repair, remanufacturing, and sustainable materials development.

- Regulatory Compliance: Help companies comply with evolving environmental regulations and reduce the risk of fines or legal liabilities associated with unsustainable practices.

- Long-Term Viability: In a world with finite resources and growing environmental concerns, circular design represents a sustainable and long-term approach to business that can adapt to changing market conditions and consumer preferences.

- Reduction of Environmental Externalities: By considering the full lifecycle of products and services, circular design helps reduce negative externalities such as pollution and habitat destruction, benefiting both ecosystems and human health.

- Improved Innovation: The challenge of designing for circularity encourages innovation in product design, material science, and production processes, driving technological advancement.

- Global Sustainability: The adoption of circular design on a large scale can contribute significantly to global sustainability goals, such as the reduction of carbon emissions and the preservation of biodiversity.

Disadvantages

- Initial Costs: Transitioning to circular design can require significant upfront investments in product redesign, supply chain reconfiguration, and new technologies. Some businesses may find these costs prohibitive, especially smaller enterprises.

- Complexity: Implementing it can be complex, as it involves redesigning products for disassembly, recycling, or reuse. This complexity may require changes in design processes and the acquisition of new skills and expertise.

- Resistance to Change: Employees, suppliers, and customers may resist changes associated with circular design, as it may disrupt established workflows, business models, and product expectations.

- Lack of Infrastructure: In some regions, there may be limited infrastructure for recycling, remanufacturing, or reusing products. Organizations may need to invest in building or improving these systems, which can be costly.

- Market Uncertainty: Circular products and services may face uncertainty in the market. Consumers and businesses may not yet fully appreciate or value circular products, potentially leading to slower adoption rates.

- Risk of Cannibalization: Introducing products designed for longevity and reuse may compete with a company’s own existing products, potentially cannibalizing sales of newer products.

- Quality Control: Maintaining the quality of recycled or refurbished products can be challenging. Ensuring that these products meet performance and safety standards is crucial for customer satisfaction and safety.

- Regulatory Hurdles: Navigating regulations related to recycling, materials handling, and extended producer responsibility can be complex and costly. Non-compliance can lead to legal and financial issues.

- Supply Chain Complexity: Implementing circular design may require changes to supply chain processes, including reverse logistics for product take-back and refurbishment. Managing these complexities can be challenging.

- Market Acceptance: Consumer behavior and preferences may not yet fully support circular products and services. Educating and convincing customers to embrace circular options can be a hurdle.

- Scale-Up Challenges: Scaling up circular initiatives to cover an entire product line or organization can be challenging, especially for larger enterprises with complex operations and multiple product categories.

- Competitive Pressure: Companies that do not embrace circular design may continue to offer cheaper, less sustainable products, creating competitive pressure on businesses transitioning to circular practices.

- Risk of Greenwashing: Companies may make circularity claims without substantiating them, potentially leading to accusations of greenwashing if their products and practices are not genuinely circular.

Examples:

- Fashion Industry:

- Patagonia Worn Wear: Patagonia’s Worn Wear program encourages customers to buy and sell used Patagonia clothing, promoting the reuse and repair of their products.

- H&M Conscious Collection: H&M introduced a Conscious Collection that uses sustainable materials, including organic cotton and recycled polyester, to create more environmentally friendly fashion.

- Electronics and Technology:

- Fairphone: Fairphone designs modular smartphones that are easy to repair and upgrade. They prioritize ethical sourcing of materials and fair labor practices.

- Apple’s Liam Robot: Apple developed the Liam robot to disassemble and recover materials from used iPhones, demonstrating a commitment to recycling and reducing electronic waste.

- Automotive Industry:

- Tesla Battery Recycling: Tesla has invested in recycling and reusing batteries from electric vehicles, contributing to the circularity of battery materials.

- Renault Re-Factory: Renault’s Re-Factory in France refurbishes and remanufactures used vehicle components, extending the life of parts and reducing waste.

- Food and Agriculture:

- Loop: Loop is a platform that partners with consumer goods companies to offer reusable packaging for everyday products, reducing single-use plastic waste.

- The Ellen MacArthur Foundation’s Food Initiative: This initiative works to eliminate food waste, promote regenerative agriculture, and create a more sustainable food system.

- Construction and Building Materials:

- Interface, Inc.: Interface, a flooring manufacturer, implemented the “Mission Zero” initiative, focusing on sustainable materials, modular design, and a closed-loop recycling system for carpet tiles.

- Mud Jeans: Mud Jeans offers a circular fashion model for denim, allowing customers to lease jeans and return them for recycling or upcycling at the end of use.

- Energy and Renewable Resources:

- Circular Solar Panels: Companies like SunPower are exploring circular design for solar panels, aiming to recover and reuse materials from old panels.

- Biomass Energy: Biomass energy production can utilize organic waste materials, creating energy while diverting waste from landfills.

- Packaging Industry:

- Coca-Cola’s “World Without Waste” Initiative: Coca-Cola aims to collect and recycle a bottle or can for every one it sells by 2030, promoting the circularity of its packaging.

- Loop’s Reusable Packaging: Loop also partners with various consumer brands to offer reusable packaging for a wide range of products, reducing single-use packaging waste.

- Textile Industry:

- Circular Systems’ Textile Recycling: Circular Systems developed technology to recycle textile waste into new fibers, contributing to a more sustainable textile industry.

- The North Face Renewed: The North Face offers refurbished and certified used clothing and gear through its Renewed program.

These examples demonstrate that circular design principles can be applied across diverse industries and product categories. They highlight the potential for reducing waste, conserving resources, and promoting sustainability in various sectors of the economy.

- You must be logged in to reply to this topic.